After 35 years of skyrocketing development of additive manufacturing, the market is full of different solutions. For the newcomer it is hard to figure out which one technology is a best fit, so the purchase decision is typically based on two factors: popularity and price.

So how most of the fresh 3D printing adepts start? They choose between FDM and SLA. Those are the most recognized technologies, that comes to mind after the phrase “3D printing” resounded in the air. Small, not so expensive and somehow glamorous in they way of printing. Watching the nozzle building layer after layer in FDM or a laser beam illuminating the resin of SLA can be fascinating. And what awaits on the other end? Industrial, looking like big metal boxes machines, costing at least hundreds of thousand of dollars. For the 3D printing rookie it is a clear information: this equipment is not for me. But aren’t there any options in between?

Digging deeper

Shane Mahon is the Network Solution Architect in a large IT company. It is his day job, but when he returns home, he becomes a Product Designer. Shane races bicycles and sometimes he wants something that no one makes. Once, he thought that maybe he could made some plastic parts or at least prototype those that will be finally made from metal. He, like a lot of people, started with a FDM 3D printer because those devices are cheap and are everywhere. After a lot of “trial and error” involved, he started to learn what he can do, and what is not possible. He met the first limitations.

- I had a need to do some rapid prototyping and low-volume production of small bicycle parts – Shane says. I have a fairly good FDM printer but I just can’t get the level of detail that I want sometimes, and I’ve had instances where support structures actually ended up ruining the print. I tried an SLA printer recently because supposedly the resolution is quite good and the one I bought was supposedly very easy to use. In seven tries I had five failures. Even the two “successes” were not really usable to test the fit of my components – he adds.

For others it would be an obvious sign, that 3D printing has its limitations, difficult to overcome by a single, home-based user. But Shane was digging deeper to find out if there is another solution. Something which he could reach for and go on with the projects. This is how he found Sintiert and its entry level desktop SLS 3D printer, Lisa.

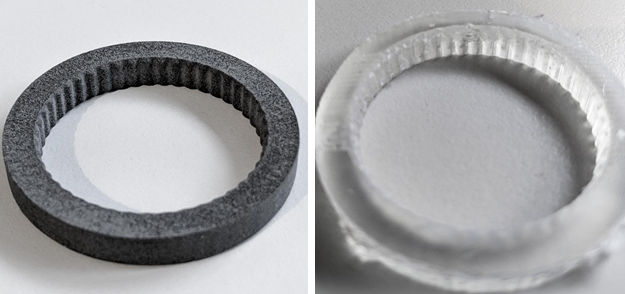

Sinterit Lisa desktop SLS 3D printed part (first try) SLA 3D printed part (best try)

- I had been thinking about the Lisa for some time so I decided to just go ahead and do it – Shane recalls. He bought Sinterit Lisa in January 2019.

It wasn’t a blind shot. Shane did a lot of research and read many reviews. He came across various SLS 3D printers. Some of them were very exotic, like from a Chinese shopping portal. The fact that Sinterit was located in Europe made it relatively easy to get in touch with somebody from the company.

- A lot of positive reviews, very good specification and being as local as you can get in this market were some of decision factors – Shane recalls. I can tell you that the hardest part of using the printer was getting it up the stairs. After that I simply unpacked it, read the instructions, prepared the printer, and let it run. The small part took a few hours to print, so I went downstairs, had dinner, watched a movie, and returned later to a cooling printer. I didn’t worry about the print going bad halfway through and coming back to a blob of melted nylon being dragged around the inside of the printer by a hot nozzle. After it finished, I simply opened it up and found my model exactly how I had imagined – he adds.

For Shane Mahon, Lisa was an answer to the need he had at the moment. At first he started printing just for himself. Later he started to prototype for friends. One of them said he wanted a mount for his cycling computer that had a bracket for the electronic shifting control box underneath. Shane tried all different kinds of settings, nozzles, support materials, everything he could think of with his FDM printer and he was never successful in getting that little bracket right.

It came out perfect on the first try with the Lisa (visible on the part on the left). There are also working hinges as an added bonus.

- So what does Lisa do for me? It saves me a lot of time first of all. It saves me from messy cleanups. Working with the powder is quite easy, and since both the software and the printer help me measure it, I don’t waste any. That saves me money. Most of all though, it saves me headaches and lets me get on with testing and building things. Which is why I bought a 3D printer in the first place – sums up Shane.