Every building you walk into, every factory that keeps running, and every commercial space that functions smoothly exists because of skilled tradespeople. We tend to celebrate technology and innovation, and rightly so. But behind every piece of infrastructure is a welder, a machinist, a fabricator, or an engineer who made it all come together with their hands and expertise. This article explores why skilled trades continue to be essential and how they shape the industries we depend on every day.

Why Skilled Trades Remain the Backbone of Industrial Growth

The Irreplaceable Value of Hands-On Expertise

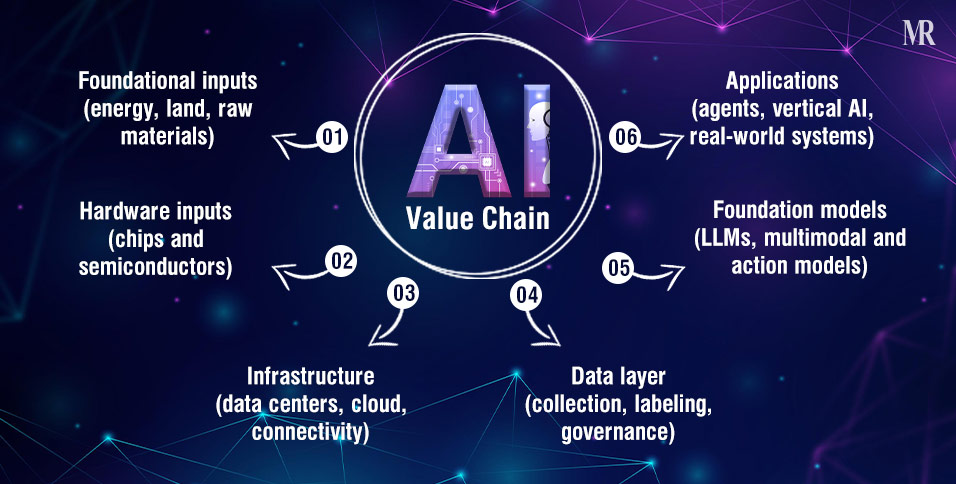

There is no question that automation and artificial intelligence have changed the way many industries operate. But here is something that often gets overlooked. When a piece of machinery breaks down on a factory floor, no algorithm is going to fix it. When a building needs custom ductwork that fits an unusual layout, no software is going to bend and weld that metal into shape.

Skilled trades like engineering, machining, welding, and fabrication require a combination of technical knowledge, physical precision, and real-time problem solving that technology simply cannot replicate. Whether it is a food processing plant, a packaging facility, or a commercial construction site, these industries depend on trade professionals showing up and getting the job done right.

The Global Skilled Labour Shortage and Its Consequences

One of the biggest challenges facing industries today is the growing shortage of skilled tradespeople. Across the world, experienced workers are retiring faster than new ones are entering the field. Apprenticeship numbers have been declining for years, and the gap is starting to show.

Projects are getting delayed. Costs are going up. Businesses are struggling to find reliable partners who can deliver quality work on time. This shortage is pushing more companies to seek out specialist firms that can handle complex work in-house without relying on subcontractors or patchwork solutions.

How Specialist Service Providers Keep Operations Running

The Rise of Full-Service Industrial Partners

If you run a business that depends on machinery or equipment, you know how frustrating it can be to juggle multiple contractors. One company for repairs, another for parts, someone else for installation. It adds up quickly in both cost and coordination headaches.

That is why more businesses are turning to partners who can do it all under one roof. From diagnostics and custom machining to installation and ongoing maintenance, having a single reliable team simplifies everything. Across industries, mechanical and engineering companies are being trusted to manage the full lifecycle of industrial equipment. These firms handle emergency breakdowns, build preventive maintenance schedules, and even manufacture replacement parts in-house when originals are no longer available. The result is less downtime, fewer surprises, and operations that actually run the way they should.

Long-Term Partnerships Over One-Off Transactions

There is also a noticeable shift happening in how businesses approach their trade relationships. Instead of calling someone new every time a problem comes up, more companies are building long-term partnerships with their service providers.

And it makes sense. A partner who has worked with your equipment for years understands its quirks, knows its history, and can spot potential issues before they become expensive problems. These relationships are not built through flashy marketing. They are built through consistency, reliability, and showing up when it matters most. In many cases, the best trade firms grow almost entirely through word of mouth and repeat business from clients who trust them.

The Critical Role of Fabrication in Commercial and Residential Projects

Where Fabrication Meets Architecture and Construction

When most people think about construction, they picture concrete, timber, and glass. But behind the walls and above the ceilings of every modern building, there is a significant amount of custom metalwork that makes the whole thing function.

Ventilation and HVAC ductwork, kitchen extraction systems, architectural cladding, stainless steel fittings, structural supports, rain covers, and flue systems are all products of skilled fabrication. These are not items you pick off a shelf. Each project has unique dimensions, performance requirements, and design specifications that demand precision craftsmanship. The quality of this metalwork directly impacts how well a building performs, how long it lasts, and how safe it is for the people inside.

Why Local Expertise Gives Projects an Advantage

Working with fabrication specialists who understand your local environment makes a real difference. They know the building codes, they understand the climate conditions, and they can respond quickly when timelines shift or designs change mid-project.

In growing urban centres around the world, experienced steel fabricators Christchurch professionals and similar specialists play a vital role in delivering quality metalwork for both commercial and residential developments. Local fabricators who offer complete service, from initial design through manufacturing and on-site installation, help reduce the coordination issues that often slow projects down. When one team owns the entire process, there are fewer gaps, fewer miscommunications, and a much higher standard of finished work.

How Technology and Tradition Work Together in Modern Trades

Advanced Tools With Traditional Craftsmanship

Walk into a modern trade workshop, and you will see an interesting mix. CNC machines sit next to manual welding stations. CAD software running on screens while a fabricator checks a finished piece by hand. Plasma cutters make precision cuts that would have taken hours just a few decades ago.

Technology has made tradespeople faster and more accurate, but it has not replaced the need for skill and judgment. A CNC machine can cut a component to exact specifications, but someone still needs to programme it correctly, inspect the output, and understand how that part fits into the bigger picture. The best workshops are the ones that blend both worlds effectively.

Investing in the Next Generation of Skilled Workers

If we want these trades to continue thriving, investing in the next generation is not optional. Apprenticeship programmes, hands-on training, and mentorship from experienced professionals are the foundation of a strong workforce.

Firms that take training seriously tend to maintain higher quality standards and build stronger reputations over time. They are also better positioned to grow sustainably because they are not constantly scrambling to find qualified workers. The knowledge that gets passed down on the workshop floor is just as valuable as any formal education, and it is what keeps these industries moving forward.

Conclusion

Skilled trades are not fading into the background. If anything, they are becoming more important as infrastructure demands grow and industries evolve. The professionals who maintain machinery, fabricate custom metalwork, and keep operations running are the ones holding it all together. Businesses that invest in strong partnerships with reliable trade specialists are setting themselves up for long-term success. As technology and craftsmanship continue to work side by side, the future of infrastructure development looks both innovative and deeply rooted in hands-on expertise.

Frequently Asked Questions

Why are skilled trades important for infrastructure development? Skilled trades provide the hands-on expertise needed to build, maintain, and repair the physical systems that infrastructure depends on. Without qualified tradespeople, construction projects stall, machinery breaks down, and the quality of finished work drops significantly.

What industries rely most on trade professionals? Manufacturing, commercial construction, energy, food and beverage processing, hospitality, and residential development all depend heavily on skilled tradespeople. These professionals handle everything from equipment maintenance and repairs to custom fabrication and installation work.

How is technology changing traditional trade workshops? Modern workshops now use tools like CNC machines, plasma cutters, and CAD software alongside traditional welding and manual fitting techniques. This combination allows for faster turnaround times and higher precision while still relying on the judgment and expertise of skilled workers.

Why do businesses prefer working with full-service trade partners? Full-service partners handle everything from initial consultation and custom manufacturing to installation and ongoing support. This reduces the need for multiple contractors, minimizes miscommunication, and helps keep projects on schedule and within budget.