If you are searching for micro coil winding, you are probably not just curious. You are dealing with a real problem.

Maybe your device is small, but the performance requirements are big. Maybe you need reliability, accuracy, and zero tolerance for error. Or maybe you are building something where even a tiny coil failure can shut down the entire system.

That is exactly why micro coil winding matters.

Let’s break it down clearly, step by step, so you know what to look for and why it matters.

What Is Micro Coil Winding, and Why Is It Different?

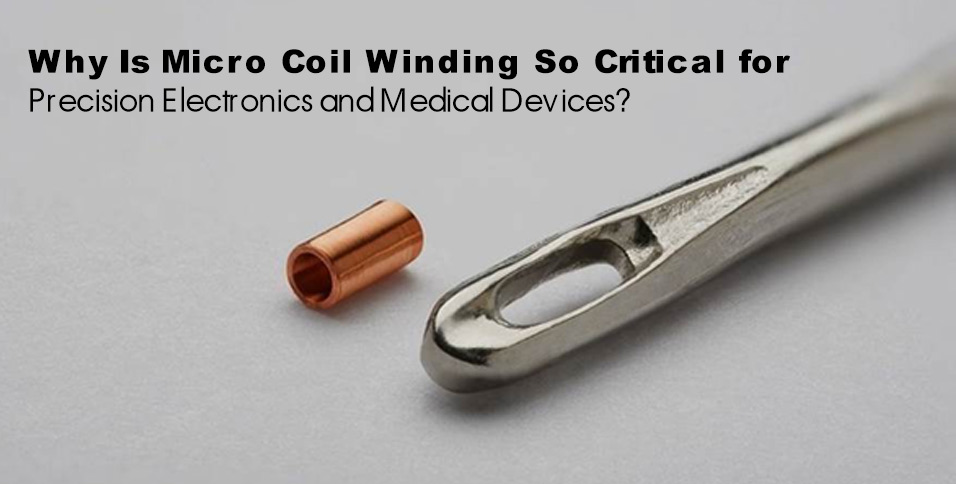

Micro coil winding is the process of winding extremely fine wire into very small, precise coils. These coils are often used where space is limited, but performance must stay perfect.

This is not basic coil winding. This is high-precision work.

Micro coils are commonly used in:

- Medical devices

- Micro soldering assemblies

- Sensors and actuators

- Solar and energy systems

- Compact electronics

A single mistake in tension, spacing, or insulation can affect:

- Signal accuracy

- Power efficiency

- Heat control

- Device lifespan

That is why precision coil winding is treated as a specialized skill, not a general service.

Why Do Medical and Precision Devices Depend on Micro Coil Winding?

Medical and precision electronics rely on consistency.

There is no room for “almost correct.”

Micro coils are often responsible for:

- Signal transmission

- Magnetic control

- Power regulation

- Motion sensing

If a coil is uneven or poorly wound, the device may:

- Overheat

- Lose signal strength

- Fail under continuous use

That is why companies working with medical devices or micro soldering usually search deeply before choosing a coil winding solution. They are not just buying a part. They are protecting their product.

Step-by-Step: What Makes a Micro Coil Reliable?

Here is what actually matters when it comes to quality micro coil winding.

1. Wire Control and Precision

Micro coils use ultra-fine wire. Even slight tension changes can damage the wire or affect performance.

2. Consistent Coil Geometry

Every turn must be evenly spaced. Irregular winding leads to signal loss and heat issues.

3. Proper Insulation

Insulation is not optional. It protects against short circuits and long-term wear.

4. Application-Specific Design

A coil for a medical sensor is not the same as one for a solar component. Design must match the exact use case.

5. Testing and Verification

Reliable micro coil winding always includes testing for resistance, continuity, and durability.

When all these steps are done correctly, the result is a coil you can trust.

Common Problems People Face When Searching for Coil Winding Solutions

If you are here, you might have already experienced one of these:

- Coils failing after short usage

- Inconsistent performance across batches

- Overheating issues

- Signal instability

- Difficulty integrating coils into micro assemblies

These problems usually come from poor winding control or lack of precision.

That is why understanding micro coil winding before choosing a solution gives you confidence. You know what questions matter.

Why This Knowledge Helps You Make Better Decisions

When you understand the process, you stop guessing.

You stop settling. You know what quality looks like. You know what risks to avoid. And you feel confident moving forward with your project.

That is the real goal.

FAQs:

Is micro coil winding only used for medical devices?

No. It is also widely used in electronics, sensors, micro soldering, and solar systems.

Why does coil size matter so much?

Smaller coils require higher precision, and small errors create big performance issues.

Can micro coils handle long-term use?

Yes, when properly designed and tested, they are built for durability.