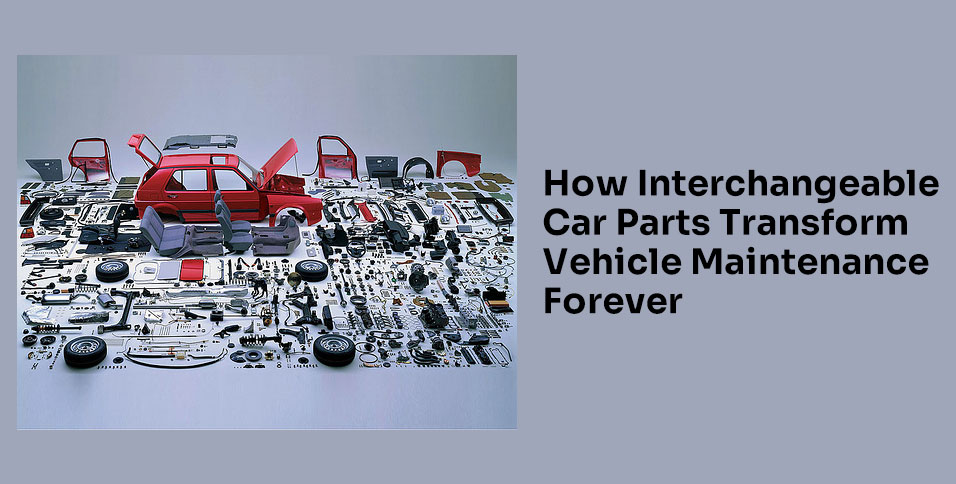

The automobile industry has experienced a huge transformation over the last hundred years where manufacturers are starting to make use of standardized parts in a number of different vehicle models and brands. The shift towards interchangeable car parts is one of the most helpful trends that can be adopted by car owners, mechanics and the automotive ecosystem in general. Being aware of the advantages of these universal components will make a great impact on your attitude towards the auto maintenance, the cost of repairing the car, and the long-term ownership strategy.

1. Dramatic Cost Reduction Through Expanded Options

Prices naturally decline across the automobile supply chain due to the competitive market circumstances created by interchangeable parts. Customers gain from more competition and wider price ranges when several vendors supply compatible parts. Car owners have a range of aftermarket choices that meet the same performance standards as those of original equipment manufacturer parts and in some cases, which are relatively expensive. This broader selection often saves up to thirty to fifty percent, as compared to brand specific parts, which makes it more affordable to all when compared to brand specific parts.

2. Enhanced Availability and Faster Repair Times

Wait periods and inventory shortages that affect vehicle-specific components are decreased by universal compatibility, which makes parts more easily accessible from a variety of suppliers. The effectiveness of the supply chain is increased when mechanics and parts stores serve a greater variety of vehicles while keeping fewer total goods in stock. Rather than order specialty parts that can take weeks to reach you, interchangeable parts can often provide the same-day service when your car is in need of repairs. This universal compatibility also benefits those selling car for parts, as standardized components maintain broader market appeal and can be more easily matched to potential buyers’ needs. To car owners, this added availability translates to less downtime, reduced labor costs along with a shorter time to resume their usual driving routines.

3. Simplified Maintenance and Repair Procedures

Standardized parts frequently have comparable installation methods and requirements for many cars, which simplifies repairs for both expert technicians and do-it-yourselfers. By employing the same components, technicians who are experienced with one vehicle system may more readily work on others, cutting down on diagnostic time and any mistakes. Repair businesses can effectively serve a wider spectrum of clients thanks to this knowledge, frequently passing labor cost savings on to customers. Additionally, streamlined processes lessen the possibility of installation errors that can result in further troubles or warranty problems.

4. Increased Vehicle Longevity and Performance Options

With interchangeable parts, car owners will not be limited to the specifications and can choose parts that would suit their driving needs and performance goals. With standardization of parts across multiple applications, high performance options, heavy duty options, or more economical parts are available. This customization allows customization depending on individual preference to extend the life of a vehicle, improve performance, or reduce the running costs.

5. Environmental Benefits Through Reduced Waste

Standardization reduces wastage of production by allowing companies to produce less unique parts, but the same quantity produced satisfies the market demand. Also, interchangeable elements can extend the life of vehicles, as these elements ensure that repair options are available longer, eliminating the risk of the automobiles to land up in the junkyards prematurely. Components that suit various cars make used parts markets more viable and open up recycling options for both customers and the environment.

Conclusion

When thinking about replacing parts for your automobile, be sure the replacements meet or surpass the original requirements and thoroughly investigate compatibility. To ensure correct fitting and performance characteristics, check trustworthy automotive databases, consult skilled mechanics, or get in touch with component manufacturers directly. Select trustworthy producers with established track records and suitable guarantees since quality should never be sacrificed for financial savings.